25 years of innovation and evolution

Heat treatment of critical components. How to ensure lasting quality.

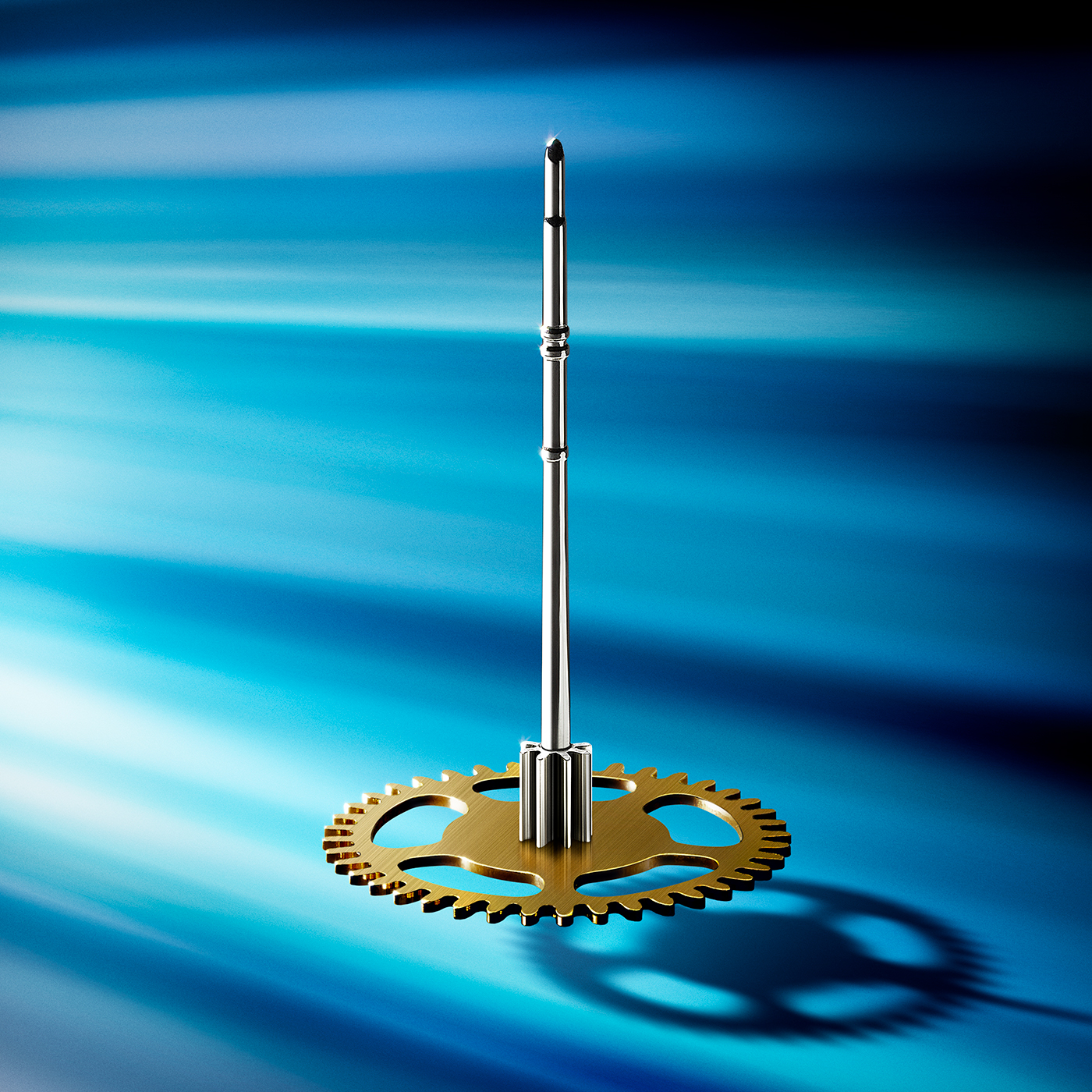

It is a brutal truth but a mechanical watch is only as good as its weakest part. In the gear train and other sections of the movement, many parts mesh and interlock with one another at speed and with considerable force, so it is vital that all these components have the highest possible levels of strength and durability.

Some of the most critical components, such as the pinion of the fourth wheel in the gear train in Caliber 9S85, are put through a quenching and tempering process that ensures their longevity and precision. First the quenching; the parts are heated in a high-temperature furnace and then cooled, a process that gives them the required strength. Next, the tempering; the parts are placed in a different furnace and heated again, this time at a lower temperature, which adds the robustness and resistance to wear and tear that is required to ensure their durability.

Conducted entirely in-house, the whole process is time-consuming, labor-intensive and requires great skill. But if that’s what it takes, Grand Seiko does it. Because perfection is the aim of each and every one of Grand Seiko’s own craftsmen and women.